The Challenge

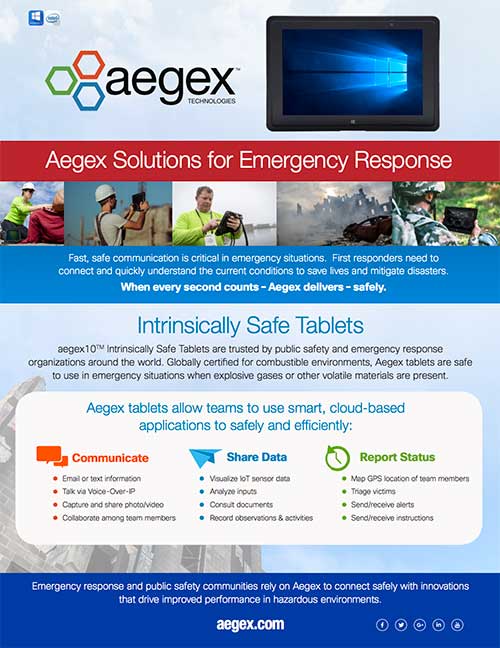

Although the facility is moving toward full digitization, there is one major problem: approximately 15% of the refinery’s workforce operates in areas of the plant that are classified as UL913 Class I Division 1 hazardous locations, where combustible materials are constantly present and only specially certified electronic equipment is permitted. The remaining 85% of the workforce works in zones classified as UL913 Class I Division 2, where combustible materials are present only in the event of a fault in equipment. However, these Division 2 areas immediately become Division 1 if a leak or rupture causes flammables to escape an enclosure, and many employees move throughout the facility at some point during their shift. Traditional smartphones and tablets cannot enter these Division 1 areas because they produce energy sufficient to cause a spark that could ignite the explosive atmosphere. Thus, workers in these zones are restricted to recording data with pen and paper and then later entering it into a desktop computer or other less-certified mobile device in a less-volatile zone of the plant. Unlike their colleagues in less dangerous areas who have replaced paper-based processes with digital reporting and communications, the Division 1 workers cannot receive nor transmit real-time information from within their work areas. The Division 2 workers who have begun to digitize their processes with corresponding certified mobile devices are limited in their mobility to only certain zones of the plant, and run the risk of adding explosive potential should an emergency arise.