The Challenge

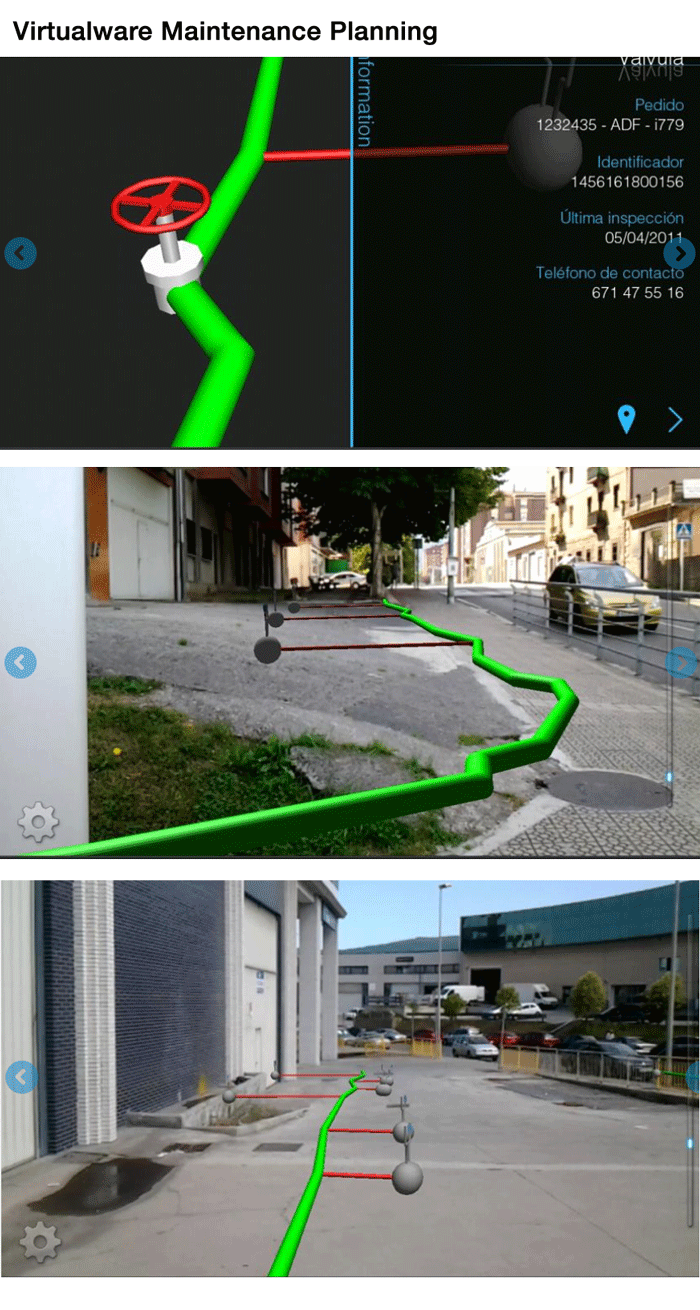

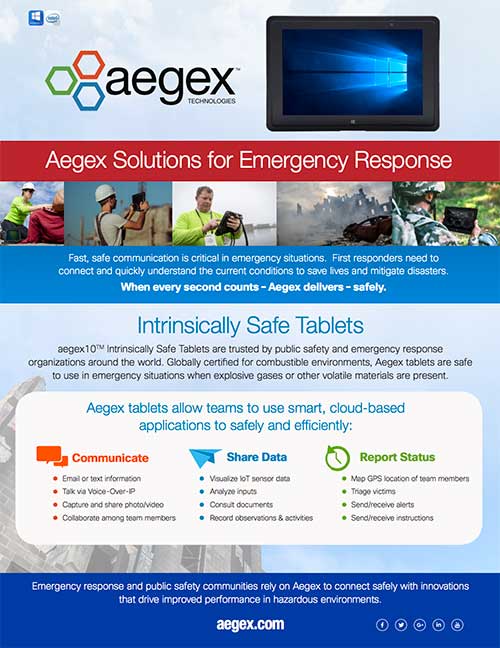

Proper maintenance and inspection are paramount in the electrical utility industry. A majority of underground electrical systems are classified as hazardous locations where highly combustible materials are present. Maintenance operators and inspectors must use equipment that is certified as ATEX/IECEx Zone 1 safe, because non-certified equipment could cause a spark that could potentially ignite an explosion. Many maintenance crews still use pen and paper to document conditions in the field sites then spend additional time and effort entering data into digital systems, increasing the chance of errors in data capture and reporting.