Accurate Feedstock Traceability

From Bin to RINTM

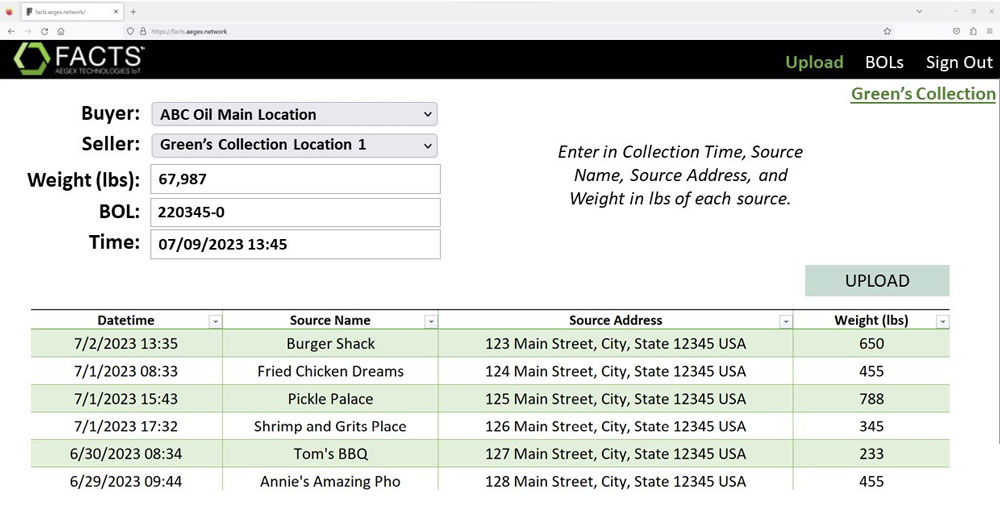

The Feedstock and Compliance Tracking System (FACTS™) is a complete end-to-end track and trace solution to manage separated food waste recordkeeping requirements. FACTS anonymously matches UCO collection data to specific renewable fuel production batches, while providing QAP providers with access to source data. Aegex is a leading technology provider in the oil & gas industry and independent of any industry stakeholder. Aegex developed FACTS to provide a powerful system that ensures our customers can comply with EPA regulations, while remaining independent of any industry stakeholder to ensure data integrity and information confidentiality

Learn More about FACTS:

Bin to RIN traceability to comply with recordkeeping requirements

Modular platform that scales to your needs

Key Benefits for renewable fuel producers and collectors/aggregators

Modular Platform

FACTS is a modular system so it can grow with you and your specific needs. Our standard solution is designed to give Renewable Fuel Producers a quick and simple way to comply with the EPA regulations. Add-on modules are designed to enable greater process management, operational efficiency, KPI’s and reporting and carbon intensity tracking of feedstocks used in the production of Renewable Fuels.

| Product | Description | Features |

| FACTS Standard Solution | Upload portal for locations of pickups and BoL's |

- Collector/Aggregator Portal

- Dedicated unique database - Anonymized BoL access provided to buyers - Auditor Portal access for Renewable Fuel Producers |

| Add-on Modules | ||

| Bin Measurement | Sensor to improve pick-up scheduling, enhance audit trail, and route planning |

- Bin Level Sensors

- Management and Routing software |

| 3rd Party Fleet Solution Integration | Integrate existing fleet solutions into FACTS | - Enhanced traceability with existing systems |

| Plant Management Solution | Manage all inbound and outbound oil, enable carbon intensity scores for processing, and optimize mass balancing |

- Tank level measurement system and sensors and/or integration

of existing systems - Enhanced traceability and cleaner audit trail - Plant management system and dashboards |

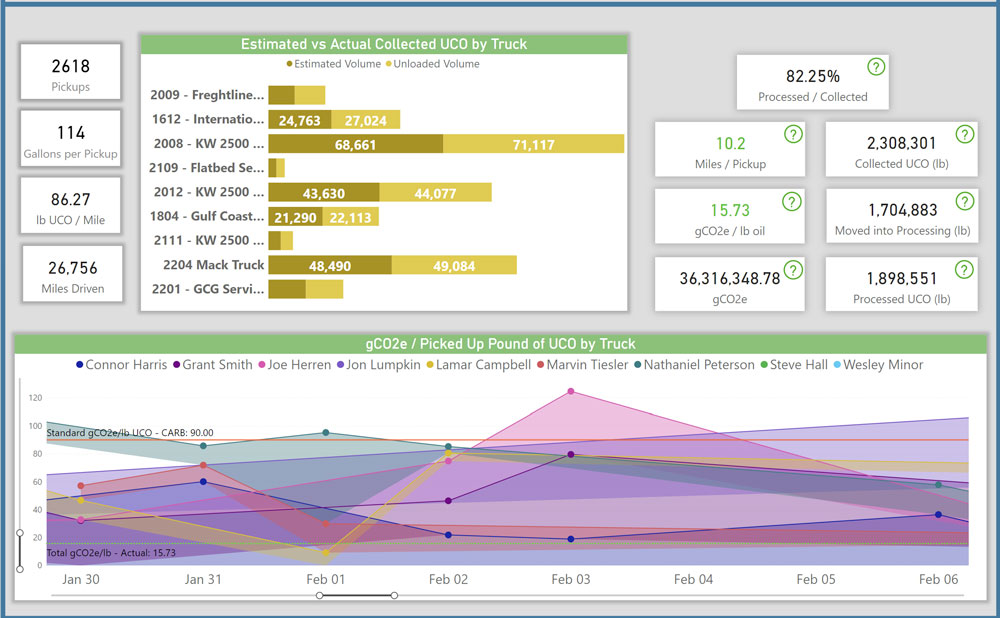

| CARB Batch Scoring | Batches scored according the GREET 3.0 system Note: system requires vehicle GPS and Plant Management Solution Module |

- Scoring of each batch based on miles driven, fuel, plant

power, and other required data - Route scoring to enhance efficiency and lower batch scores - Trend lines of routes and drivers to drive operational efficiency |

| RIN Mass Balancing | Tracking loads received into renewable fuel production to ensure accurate mass balancing records for EMTS uploads to EPA | - Certified Intrinsically Safe tablets and sensors for use in refineries to improve operational efficiency, information management, and safety |

Key Benefits

On June 21, 2023, the EPA announced their updates to the Renewable Fuel Standard (RFS) Program: Standards for 2023–2025. The EPA will continue to allow third parties contracted by renewable fuel producers to maintain records of separated food waste sources’ location and amount. Aegex Technologies and its FACTS platform remain independent of any industry stakeholders to ensure confidential records management while enabling QAP providers seamless access to data necessary to conduct audits as mandated under the regulations.- Enabling UCO as a compliant feedstock by providing necessary record keeping compliance of feedstock sources in accordance with EPA regulation 40 CFR 80.1454(j)

- Low cost and easy deployment

- API integration to legacy and ERP systems

- Secure, auditable, and anonymized sources for all Bills of Lading (BoL’s)

- Producer and QAP portals for records management and audit

- Certified intrinsically safe sensors and tablets improving refinery efficiency, safety, and process management.

- Scope 3 Supply Chain Carbon Intensity (CI) of collections UCO based on the LCFS CA-GREET3.0

- RIN Mass Balance reporting

- Enabling UCO sales to renewable fuel producers by providing necessary record keeping compliance of feedstock sources in accordance with EPA regulation 40 CFR 80.1454(j)

- Simple portal for collectors/aggregators to manage source locations.

- Low cost and easy deployment

- Can integrate many existing fleet management systems to streamline processes and information management.

- Accurate Bin measurement to prevent fraud, identify theft, and improve route management.

- Plant management system to optimize feedstock processing and rendering.

- Real-time analytics and operational trendline of gCO2e generated by collection routes and operations to enable efficient low carbon pathway objectives.