The Challenge

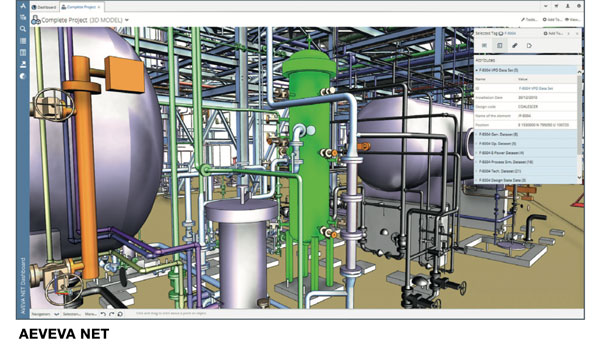

An offshore liquid natural gas operation is seeking to improve the productivity and safety of its operations while decreasing downtime and inefficiencies. With 24-hour production generating myriad data feeds about all aspects of operations, workflow and functionality, the facility operators would like to utilize that data better to understand and improve performance. However, they are not currently able to view the real-time status of the entire facility nor the performance of individual components as part of the overall operation because of the asset’s sheer size, complexity and regulatory restrictions that prevent the use of certain electronic equipment, including computing devices. The offshore operation is classified as a regulated hazardous location because highly flammable materials are constantly present in liquid or gaseous forms. Thus, any electronic equipment used in the facility must be certified intrinsically safe for ATEX Zone 1, meaning it cannot produce a spark sufficient to cause an explosion. Personnel performing inspections, maintenance, or other tasks in the facility must move through various hazardous zones as they go about their work. Because the team cannot bring typical computing devices into the hazardous zones, individuals currently write down information with paper and pen onsite – including data on pump volume and performance, gauge pressure, and other metrics. They then use various software on computers in an off-site location to plan solutions for future implementation. The process is, thus, time-consuming and causes delays to optimizing productivity.